Polybutylene Piping Problems Uncovered in Perth

8 Min Read – Author: Timothy Intveld, Qualified Leak Detector,

Founder of Wizard Leak Detection Mandurah

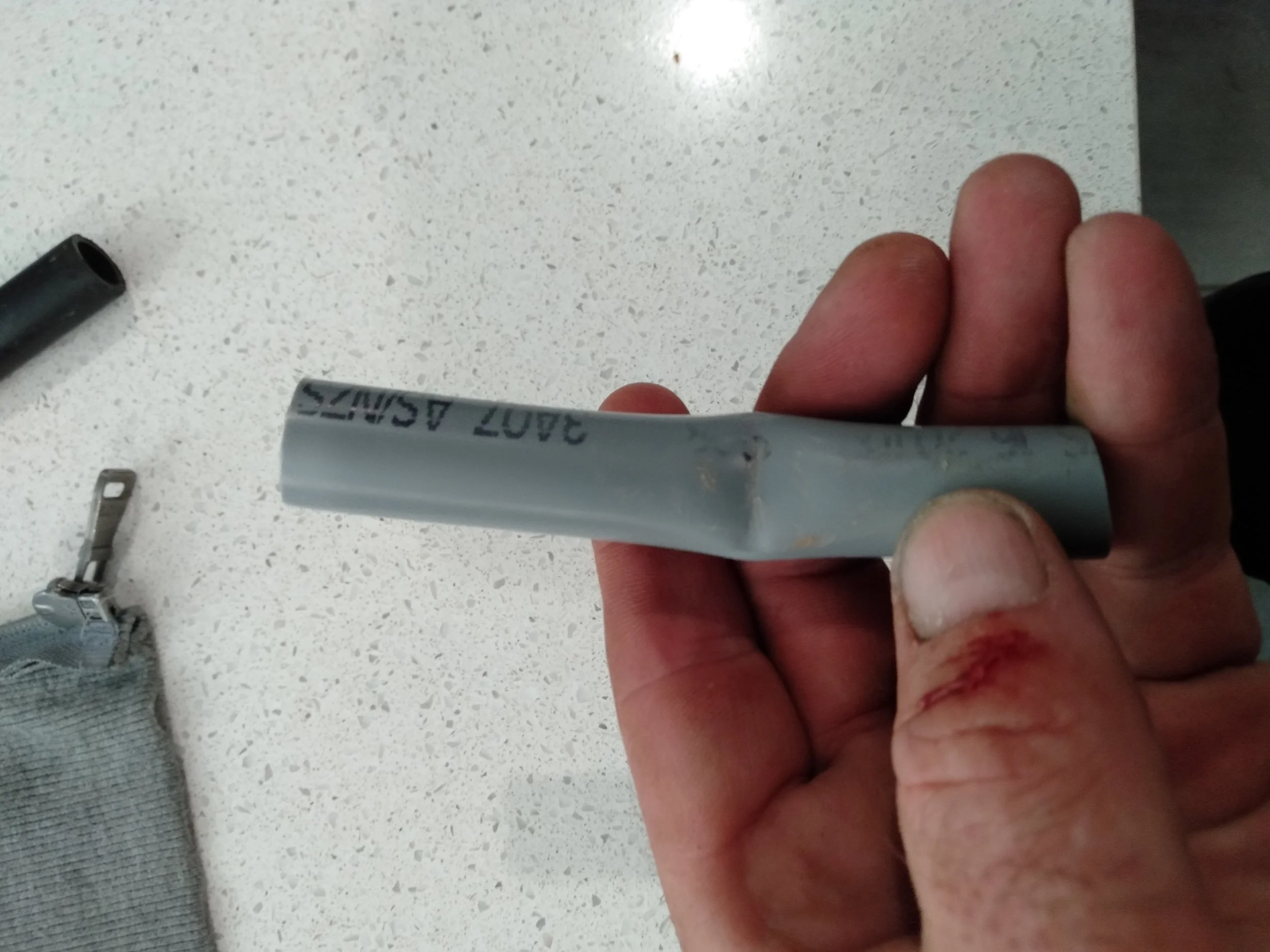

Polybutylene piping, a type of plastic plumbing material, is used widely in Perth Australia under several brands. In Canada it was widely used in residential and commercial construction from the late 1970s to the mid-1990s. It was popular due to its low cost, easy installation, and flexibility.

However, Canadian homeowners started experiencing various issues with this type of plumbing, leading to class-action lawsuits, increased awareness, and significant changes in plumbing practices.

Now it is being discovered in Perth, Australia that this type of piping is prone to various issues, including leaks, bursts, and general deterioration, causing major problems for Australian homeowners. If you need leak detection services in Mandurah, contact Wizard Leak Detection Mandurah to assist you.

This comprehensive guide aims to provide an in-depth understanding of the issues associated with polybutylene piping in Australia, the reasons behind these problems, and possible solutions to mitigate the risks and damages caused by this type of piping. If you suspect you have a leak, check out our service areas page. We serve all suburbs surrounding Mandurah.

Key Takeaways Details

Polybutylene Piping Issue Defective nature causing leaks, damages & costly repairs in both Canada and Australia

Canadian & Australian Experience Banned in Canada; awareness of risks and potential issues in Australia

Factors Affecting Failure Rate Manufacture location, transportation, storage, installation – applicable to both countries

Selling and Buying Homes with Polybutylene Pipes Impact on home value, negotiations & insurance coverage in both countries

Replacement Process Protecting the home, replacement, restoration, and cleaning – similar approach in both countries

Importance of Experienced Contractor Expertise, communication, project management, quality work – crucial in both Canada and Australia

Replacement Options Class C, Class B, and Class A PEX Piping – available alternatives in both countries

Key Responsibilities of Contractors Plumbing, taping, painting, texturing, and proper cleaning – standard process in both countries

Wizard Leak Detection featued in this article for WA Today

What the Government says regarding water leaks cause by Polybutylene piping in Perth:

The government confirms that some new homes, specifically those built around 2019 and 2020, are having a bit of a plumbing predicament. It seems there’s a certain brand of polybutylene pipes that’s not holding up too well, resulting in leaks and water damage.

Now, you might be wondering, “What’s the brand?” Honestly, we’re all a bit in the dark on that one as Building and Energy is still doing their detective work to figure it out. In the meantime, they’ve set up an online register where you can report if you’ve had these pipes installed in the last six years, even if you’ve not had any problems…yet.

A word of caution though, if you see any water stains on your walls, ceilings, or floors, or if your water bill mysteriously spikes, these could be signs of a burst pipe. If you’re experiencing any of this, it’s a good idea to get in touch with your builder or, if you’re renting, your landlord or property manager.

The investigation is ongoing and any updates will be posted on the Building and Energy website. If you’re left feeling a bit anxious about all this, you can reach out to Building and Energy at 1300 489 099 for more info.

As always, we’re here at Wizard Leak Detection Mandurah to help with any leak detection needs.

Researchers have studied why polybutylene pipes fail and have developed ways to predict how long they might last. They found that the lifetime of these pipes mainly depends on how long it takes for cracks to start forming and growing¹. By studying how cracks form and grow, researchers have been able to create models to estimate how long these pipes will last.

There are several factors that can cause polybutylene pipes to fail, including manufacturing conditions, transportation and storage, installation processes, and the chemicals in the water supply. Homeowners should be aware of these factors when dealing with polybutylene pipes and consider replacing them with more reliable and durable alternatives.

How to Replace Polybutylene Pipes – This Old House. https://www.thisoldhouse.com/plumbing/21017106/how-to-replace-polybutylene-pipes

Should You Replace Polybutylene Piping In Your Home? https://www.rsandrews.com/blog/replace-polybutylene-piping-home/

Poly B Replacement: How To Replace Grey (Polybutylene) Pipes – YouTube. https://www.youtube.com/watch?v=Pcugxd1n3zg

Polybutylene – Wikipedia. https://en.wikipedia.org/wiki/Polybutylene

Replacement Piping Options:

Class C PEX Piping (Low-Grade):

Rated for 80-100psi, this type of piping has low resistance to high heat and may burst if frozen. Estimated life expectancy is 50 years.

Class B PEX Piping (Mid-Grade):

Rated for 100-110psi, this piping is cross-linked and has adequate freezing and heat-resistant prevention qualities. Estimated life expectancy is 50 years.

Class A PEX Piping (High-Grade):

Rated for up to 497psi, this piping is highly durable and can withstand extreme heat and freezing. Estimated life expectancy is 100+ years.

Issues with Polybutylene Piping in Australia

One common problem that has plagued Australian homes and businesses is the use of polybutylene piping. In this report, we’ll delve into the main concerns associated with this material and its impact on Australian properties.

A. Leaks and Bursts

One of the primary issues with polybutylene piping is its propensity for leaks and bursts. These incidents can cause significant water damage to properties, leading to expensive repair costs and potential health hazards due to mould growth.

The reason for these leaks and bursts is the material’s inherent weakness, which becomes more pronounced with time and exposure to various environmental factors, such as temperature fluctuations and chemicals present in water supplies.

B. Deterioration

Polybutylene piping has been known to deteriorate over time, becoming brittle and prone to breakage. This deterioration is due to the material’s sensitivity to oxidative stress, which is caused by the presence of chlorine and other oxidants in water supplies. As the pipes degrade, they become increasingly susceptible to leaks and eventual failures. The risk of pipe failures not only poses a threat to the structural integrity of a property but can also lead to costly repairs and water damage.

C. Impact on Property Value

The presence of polybutylene piping in a property can have negative implications on its value. Potential buyers may be deterred from purchasing a home or commercial building with this type of plumbing, as they are aware of the associated risks and costs.

Additionally, insurance companies may be reluctant to provide coverage for properties with polybutylene piping, further complicating the sale process.

The use of polybutylene piping in Australian properties has been linked to a range of problems, from leaks and bursts to material deterioration and reduced property values. As an experienced leak detection and pipe repair company, we recommend that property owners consider replacing these pipes with a more reliable and durable alternative, such as PEX piping, to avoid potential issues and ensure the long-term stability of their homes and businesses.

Understanding the Factors Behind Polybutylene Pipe Failures

Polybutylene (PB) pipes were once a popular choice for home plumbing systems, but their use has declined due to reports of premature failures¹. In this article, we will break down the factors that contribute to polybutylene pipe failures in a way that’s easy for homeowners to understand.

A. Manufacturing Conditions

Pipes made in hot climates may have higher failure rates¹. This is because the high temperatures during production can affect the material, making it more prone to issues such as brittleness and cracking.

B. Transportation and Storage

When pipes are exposed to sunlight and temperature changes during transportation and storage, they can deteriorate more quickly². This means that pipes that have been exposed to sunlight or varying temperatures for a long time might be weaker and more likely to fail.

C. Installation Process

If pipes are not installed correctly, they are more likely to fail¹. This includes things like improper handling of the material, not connecting joints properly, and using parts that don’t work well together. When pipes are not installed properly, they might not be able to handle the normal pressures and conditions they would typically face.

D. Water Supply & Oxidation

Certain chemicals in the water supply, like high levels of chlorine, can cause pipes to deteriorate faster³. Research has found that chlorine can make polybutylene pipes brittle and cause them to crack over time. As the cracks get deeper, the pipes can eventually fail.

Hiring a Qualified Contractor:

a. Experience:

An experienced contractor is essential for a successful polybutylene piping replacement.

b. Communication and project management:

Ensure the contractor has proper communication skills and project management software to document the process.

c. Responsibilities:

The contractor should coordinate with all necessary professionals, including plumbers, tapers, painters, and textures.

The replacement process involves three steps:

First establish whether you have a leak by checking your water meter. If you discover over a period of time that your water pipes are leaking, contact Wizard Leak Detection to find and repair the immediate leak.

A. Protecting the Home

Before any pipe replacement work begins, it’s crucial to protect your home and belongings from dust and debris. This involves:

Covering furniture with plastic sheets or drop cloths to prevent dust and debris from causing damage.

Placing plastic wrap or carpet protectors over carpets and other flooring to keep them clean and safe.

Sealing off rooms that aren’t being worked on with plastic sheeting and tape to minimize the spread of dust throughout the house.

Removing or relocating any valuable or fragile items to ensure they are not accidentally damaged during the process.

B. Replacing the Pipes

Once the home is protected, the process of replacing the polybutylene pipes begins. This involves:

Locating and accessing all active polybutylene piping throughout the house, which may require cutting into walls, ceilings, or floors.

Removing the old, deteriorated polybutylene pipes and properly disposing of them.

Installing new, more reliable piping material, such as CPVC (chlorinated polyvinyl chloride) pipe¹, which offers better resistance to heat, cold, chemicals, and corrosion.

Connecting the new pipes to the existing plumbing system and testing for leaks and proper function.

C. Restoring the Home

After the pipe replacement is complete, the final step is to restore the home to its original condition. This involves:

Repairing any holes, cuts, or damage to walls, ceilings, and floors caused by accessing the pipes.

Repainting or refinishing surfaces to match the original colour and finish.

Reinstalling any fixtures, such as light switches or outlets, that were removed during the process.

Cleaning up and removing all dust, debris, and materials from the work area.

Replacing polybutylene pipes in your home is a multi-step process that involves protecting your home, removing the old pipes, installing new, more reliable piping material, and restoring your home to its original state. By understanding the details of each step, homeowners can be better prepared and make informed decisions when it comes to addressing this critical home improvement project.

Conclusion:

Polybutylene piping poses significant risks to Australian homeowners, including leaks, bursts, and reduced property value.

By understanding the issues, factors influencing failure, and possible solutions, homeowners can make informed decisions about replacing polybutylene piping in their homes.

Hiring an experienced contractor and selecting appropriate replacement piping materials can help ensure a successful remediation process and protect the home for years to come.